PLYWOOD

Plywood is wood fabrication made of solid wood that is processed into sheets with the fiber direction on the wooden layer arranged transversely between the bottom layer and the surface layer using a special adhesive.

In plywood production, a log is peeled into sheets of veneer which are then cut to the desired dimensions, dried, patched, glued together and then pressed under high temperature press to form the plywood panel. Depending on the type of log (quality, color etc.) peeled, the veneer sheets will become either face or back veneers, which are the furthest outer layers of the plywood panel, or core veneers which will form the inside layers.

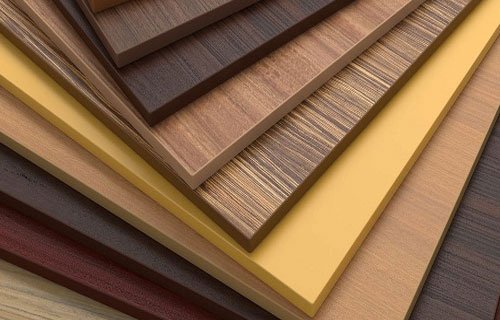

Product Types

Our plywood is known for its quality.

Our plywood is known for its quality.

Understanding that flatness and dimensional stability are essential in furniture manufacturing to bring about a perfect finishing and to minimize expansion and contraction, our range of plywood products exhibit the characteristics of being flat, dimensionally stable, durable, and of high precision. As flatness is a crucial factor in the secondary processing of plywood and is necessary for a smooth finishing, our plywood is also suitable for secondary processing.

Last but not least, general plywood can also be used in concrete framework as a cheaper option for low-rise construction work.

Characteristic

Multi Purpose

High Dimension Stability

Smooth Surface

Sustainable Wood Product

| Product Name | Wood Species Used | Product Specification | Thickness (mm) | Width x Length (mm) | Construction |

|---|---|---|---|---|---|

| Face/Back : MLH Core : Falcata/Rubber or Falcata | Palem Plywood Moisture Content : Max 14% Density : - Core Falcata / Rubber Wood : 400-550 kg/cbm - Core Falcata Wood : 300-450 kg/cbm Adhesive : T2 - Urea Formaldehyde Glue T1 - Melamine Urea Formaldehyde Formaldehyde Emission : Available : - Up to CARB Phase 2/E0 Formaldehyde Emission Level | 2,7 3,6 5,0 8,0 9,0 12,0 15,0 18,0 | 1220 x 2440 (4' x 8') | 3-9 Plies depend on thickness |

| Face/Back : Falcata Core : Falcata | Tunas Plywood Moisture Content : Max 14% Density : - Core Falcata Wood : 300-400 kg/cbm Adhesive : T2 - Urea Formaldehyde Glue T1 - Melamine Urea Formaldehyde Formaldehyde Emission : Available : - Up to CARB Phase 2/E0 Formaldehyde Emission Level | 2,7 3,6 5,0 8,0 9,0 12,0 15,0 18,0 | 1220 x 2440 (4' x 8') | 3-9 Plies depend on thickness |

| Face/Back : MLH Core : MLH | Gmelina Plywood Moisture Content : Max 14% Density : - Core MLH Wood : 500-650 kg/cbm Adhesive : T2 - Urea Formaldehyde Glue T1 - Melamine Urea Formaldehyde Formaldehyde Emission : Available : - Up to CARB Phase 2/E0/F4S Formaldehyde Emission Level | 2,7 3,2 3,6 3,7 5,0 9,0 12,0 | 1220 x 2440 (4' x 8') (available for cut size) | 3-7 Plies depend on thickness |

| Face/Back : MLH Core : Rubber | Fortuna Plywood Moisture Content : Max 14% Density : - Core Rubber wood : 600-750 kg/cbm Adhesive: T1 - Phenolic Glue (WBP) Formaldehyde Emission : - UP TO E0 Formaldehyde Emission Level | 9,0 12,0 15,0 18,0 | Up to 1250 x 2500 (4' X 8') | 7-11 Plies depend on thickness |

| GP Palem | Face/Back : MLH Core : Falcata | Moisture Content : Max 14% DENSITY: - Core Falcata Wood = 300-450 kg/cbm Adhesive : T2 - Urea Formaldehyde Glue T1 - Melamine Urea Formaldehyde Formaldehyde Emission : Available : - Up to JAS F★★★★ Formaldehyde Emission Level | 3,7 5,2 8,6 11,6 14,6 17,6 | Width 910mm / 915mm / 920mm (3') Length 1820mm / 1830mm (6') | 3-9 Plies depend on thickness |

| GP Tunas | Face/Back : Falcata Core : Falcata | Moisture Content : Max 14% DENSITY: - Core Falcata Wood = 300-400kg/cbm Adhesive : T2 - Urea Formaldehyde Glue T1 - Melamine Urea Formaldehyde Formaldehyde Emission : Available : - Up to JAS F★★★★ Formaldehyde Emission Level | 3,7 5,2 8,6 11,6 14,6 17,6 | Width 910mm / 915mm / 920mm (3') Length 1820mm / 1830mm (6') | 5-7 Plies depend on thickness |

| Product Name | Thickness (mm) | Dimension (mm) | No. Of Crates - 40'HC Container | No. Of Sheets- 40'HC Container |

|---|---|---|---|---|

| Palem Plywood | 2,7 3,6 5,0 8,0 9,0 12,0 15,0 18,0 | 1220 x 2440 (4' x 8') | 18 | 5850 4860 3960 2340 2250 1620 1314 1080 |

| Tunas Plywood | 2,7 3,6 5,0 8,0 9,0 12,0 15,0 18,0 | 1220 x 2440 (4' x 8') | 18 | 6480 4860 3780 2340 2250 1620 1314 1080 |

| Gmelina Plywood | 2,7 3,2 3,6 3,7 5,0 9,0 12,0 | 1220 x 2440 (4' x 8') | 16 | 5040 4000 3920 3680 2720 1600 1120 |

| Fortuna Plywood | 9,0 12,0 15,0 18,0 | Up to 1250 x 2500 (4' x 8') | 14 | 1400 980 840 700 |

| GP Palem | 3,7 5,2 8,6 11,6 14,6 17,6 | 910 / 915 / 920 x 1820 / 1830 (3' x 6') | 24 | 6600 5160 3000 2280 1776 1440 |

| GP Tunas | 8,6 11,6 | 910 / 915 / 920 x 1820 / 1830 (3' X 6') | 24 | 3000 2280 |

Our birch plywood is a high-quality product for a variety of applications.

This product offers smooth, flat surfaces with warm complexion and natural wood pattern. With stable, high-precision, and durable dimensional characteristics, our birch plywood is very suitable for your furniture and interior needs.

Characteristic

Flat Surface

Dimensionally Stable

Smooth Surface

Superior Strength & Durability

Sustainable Wood Product

Good Absorbance Material for Paint

Ready to Use Panel

| Wood Species | Product Specification | Thickness (mm) | Width x Length (mm) | Construction |

|---|---|---|---|---|

| Face/Back: Birch Wood Core: Falcata/Rubber or Falcata | Moisture Content : Max 14% Density: - Core Falcata/Rubber Wood = 500-550 kg/cbm - Core Falcata Wood = 320-450 kg/cbm Adhesive: T2-Urea Formaldehyde Glue Formaldehyde Emission: - CARB Phase 2 Formaldehyde Emission Level | 5.2 9.0 12.0 15.0 18.0 | 1220 x 2440 (4' x 8') | 5 up to 9 plies depend on thickness |

| Thickness (mm) | Dimension (mm) | No. of Crates - 40'HC Container | No. Of Sheets - 40'HC Container |

|---|---|---|---|

| 5.2 | 1220 x 2440 (4' x 8') | 18 | 3240 pcs |

| 9.0 | 1220 x 2440 (4' x 8') | 18 | 1800 pcs |

| 12.0 | 1220 x 2440 (4' x 8') | 18 | 1350 pcs |

| 15.0 | 1220 x 2440 (4' x 8') | 18 | 1080 pcs |

| 18.0 | 1220 x 2440 (4' x 8') | 18 | 900 pcs |

Our plywood products are the perfect choice for any interior work. We offer plywood designed with a more precise dimension as it is of great importance to interior work, particularly for flooring. We invest extensively in technology and employee development to maintain high accuracy and consistency in our products. Additionally, we only use high strength adhesives for our plywood to avoid tear out and ensure durability of your interior products. Alternatively, you may choose the glue type based on your needs.

Our plywood products are the perfect choice for any interior work. We offer plywood designed with a more precise dimension as it is of great importance to interior work, particularly for flooring. We invest extensively in technology and employee development to maintain high accuracy and consistency in our products. Additionally, we only use high strength adhesives for our plywood to avoid tear out and ensure durability of your interior products. Alternatively, you may choose the glue type based on your needs.

Characteristic

High Precision Dimension

Stable Under the Change of Temperature and Moisture

Natural Wood Appearance

Specifically Made for Producing Engineering Flooring

| Wood Species | Product Specification | Thickness (mm) | Width x Length (mm) | Construction | Characteristic |

|---|---|---|---|---|---|

| All MLH & All Falcata | Moisture Content : Max 14% Density: - Core Falcata Wood = 300-400 kg/cbm - Core MLH Wood = 450-550 kg/cbm Adhesive: T1 - Phenolic Glue (WBP) T1 - Melamine Urea Formaldehyde T1.5 - Mixture of Melamine & Urea Based Glue Formaldehyde Emission: - UP TO E0/JAS F★★★★ Formaldehyde Emission Level | 7.0 (All MLH) 9.0 (All Falcata) | 1220 x 2440 (4' x 8') 945 x 1840 (3' x 6') | 5 plies | Floorbase All MLH (F/B: MLH Core : MLH) - High Dimensional Stability - Strength & Durability - Minimal Moisture Expansion - Dense & Shock Resistant - Natural Wood Appearance - High Precision Floorbase All Falcata (F/B: Falcata Core : Falcata) - Uniform Color - Lightweight - Great Insulator - Provide Excellent Sound Damping - Sustainable Wood Product - High Precision |

| Thickness (mm) | Dimension (mm) | No. of Crates - 40'HC Container | No. Of Sheets - 40'HC Container |

|---|---|---|---|

| 7.0 | 1220 x 2440 (4' x 8') | 16 | 1808 pcs |

| 9.0 | 945 x 1840 (3' x 6') | 24 | 3000 pcs |

We provide incredibly strong, flat and durable plywood, such as the film-faced plywood, for building materials including concrete formwork. Our film-faced plywood is primarily made from rubber wood plywood covered with a protective film on both or either side of the surface. The combination of rubber wood with phenolic glue coating and quality phenolic film by Dynea provides for an excellent balance of strength to weight ratio. In addition, the water-resistant paint used for edge sealing weather-proofs our product, making it ideal for construction due to its smooth surface and scratch resistant properties. It can be used multiple times and its resistance to shrinkage makes it a very economical choice for high-rise construction purposes.

We provide incredibly strong, flat and durable plywood, such as the film-faced plywood, for building materials including concrete formwork. Our film-faced plywood is primarily made from rubber wood plywood covered with a protective film on both or either side of the surface. The combination of rubber wood with phenolic glue coating and quality phenolic film by Dynea provides for an excellent balance of strength to weight ratio. In addition, the water-resistant paint used for edge sealing weather-proofs our product, making it ideal for construction due to its smooth surface and scratch resistant properties. It can be used multiple times and its resistance to shrinkage makes it a very economical choice for high-rise construction purposes.

Characteristic

Most effective in reinforced cement concrete construction

Easy to Clean

It has smooth mirror surface in both side with precise finishing

It save up to 45% cost compare to regular plywood due to repetition in usage

Its cross laminated structure between face, core and the film enhance the strength of ply

After using it for many times (approximately up to 8 times in one side application), it can be re-used for another usage such as: partition; underlayment; temporary roofing or panelling

Sustainable Wood Product

| Wood Species | Product Specification | Thickness (mm) | Width x Length (mm) | Construction |

|---|---|---|---|---|

| Face /Back : Film Core : Rubber | Moisture Content : Max 14% Density: - Core Rubber Wood = 600-750 kg/cbm Adhesive: T1 - Phenolic Glue (WBP) Formaldehyde Emission: - Up to E0 Formaldehyde Emission Level Film Color : Brown | 12.0 15.0 18.0 21.0 | 1220-1250 x 2440-2500 (4' x 8') | 7-11 plies depend on thickness |

| Thickness (mm) | Dimension (mm) | No. Of Crates - 40'HC Container | No. Of Sheets- 40'HC Container |

|---|---|---|---|

| 12.0 | Up To 1250 x 2500 (4' x 8') | 14 | 980 pcs |

| 15.0 | Up To 1250 x 2500 (4' x 8') | 14 | 840 pcs |

| 18.0 | Up To 1250 x 2500 (4' x 8') | 14 | 700 pcs |

| 21.0 | Up To 1250 x 2500 (4' x 8') | 14 | 602 pcs |

Range of Applications

Long-lasting products are investments.

If you need a long-lasting, durable, and strong material for your home or building construction, our LVL is your right choice. Moreover, we offer termite-resistance option to protect the product from termite and insects. You would not need to replace your home material often due to rotting, molding, and termite damage. To tailor your needs, we offer a high range of customized LVL productsfor a various of applications.